We use cookies on our website to provide you with the best user experience. If you're happy with this please continue to use the site as normal.

For more information please see our Cookie Policy.

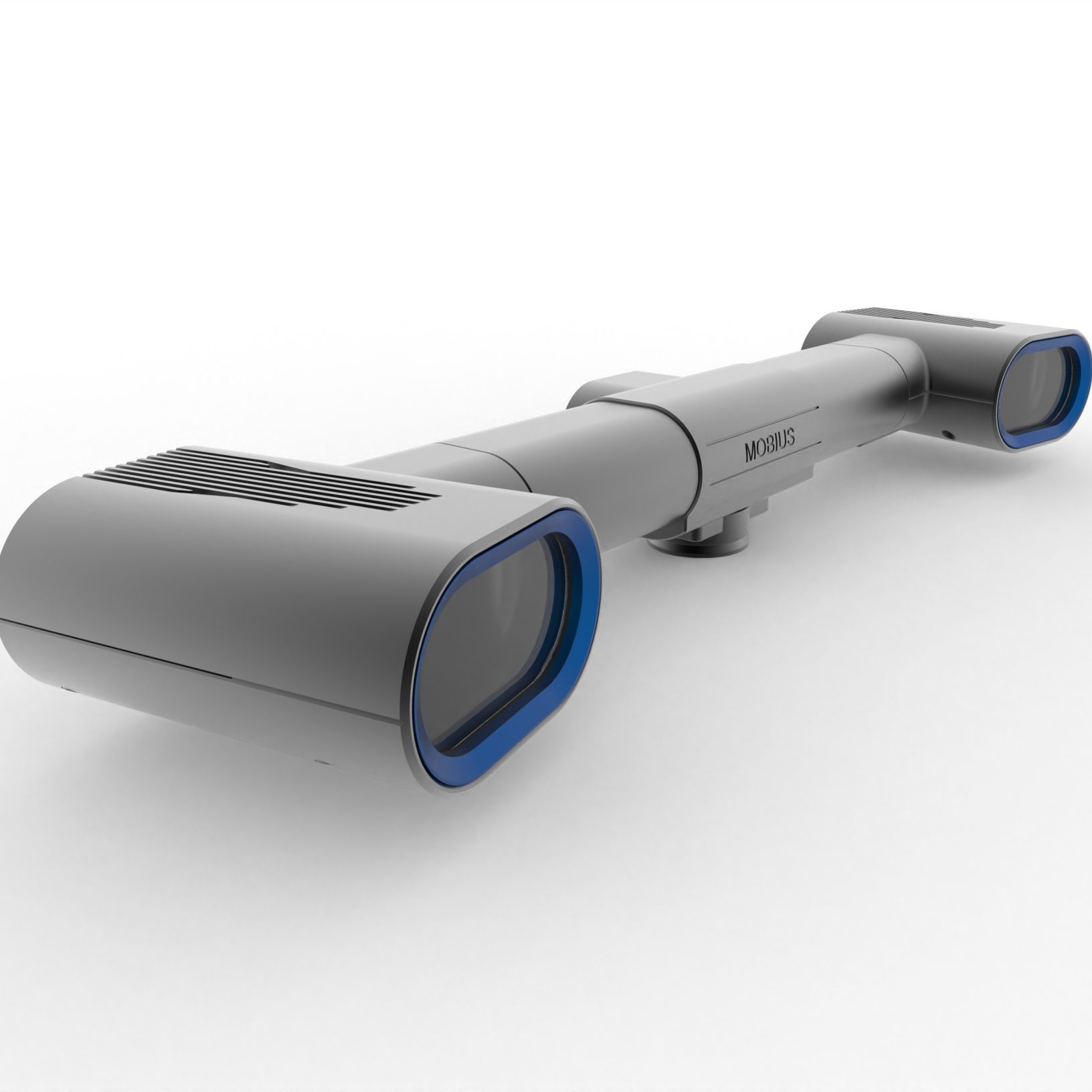

Mobius is a dynamic 3D measurement system that provides class leading accuracy and resolution, combined with the most data-rich output of any 3D Digital Image Correlation system available today. The Mobius system combines an industrially ruggedised stereoscopic optical head with one of two high performance processor platforms running Imetrum’s Video GaugeTM software.

Mobius is suitable for precision displacement, position, rotation and strain measurement in dynamic applications across a range of industry sectors such as, Aerospace, Industrial and Process Plant, Energy Systems, Scientific Research and many more. All measurements are non-invasive meaning, for example, airflow is not disrupted during aerodynamic testing or that material properties are not altered by the physical mounting of the sensor. Non-contact also means the elimination of the time and effort required to correctly install and calibrate contacting sensors in highly sensitive or hard to reach locations.

Supplied as a fully-integrated and pre-calibrated unit requiring minimal setup and user calibration, a single Mobius unit is able to completely replace numerous conventional sensors such as LVDTs, DTIs, EDMs, encoders, laser trackers and potentiometers.

New enhanced features such as Rigid Body Motion Correction (RBM) and Unified Coordinate System (UCS) complete a broad and full featured toolset.

Features and benefits

- Truly Non-Contact 3D Measurement system

- Significantly reduces test setup times, potentially from days to hours in some applications

- Allows for post process of video files – endless measurement adjustments are possible long after the physical test is complete

- High-speed capture frequencies up to 300Hz

- Resolution of better than 0.1 micron possible

- Accuracy typically better than 0.3% of reading

- Available in standard 1m3 and 3m3 measurement volumes

- Customer defined application specific measurement volumes available to order

- Ruggedised and stylish all metal housing to allow for real world implementation

![]()

- Serviceable lens protection glass reduces damage risk and costly testing downtime

- Suitable for portable or fixed mounting installations in any orientation

- Synchronised multi-head system capability via a single controller/software licence

- 3D strain-maps available in post processing

- Real-time software/testing control via data acquisition interface for external control system integration

- High performance processor and data storage options available to support high bandwidth data acquisition and processing requirements

![]()

Videos

Introducing Mobius